Commercial Jerky Dehydrator

Short Story:

Erik, an owner of Mika & Sammy’s Gourmet Pet Treats, recently tested our dehydrator AirFlow 130. His company had been using 10 food dehydrators, which took 24 hours to process his product. After inspecting how the Airflow 130 was built, he tested out the dehydrator with his jerky treats for dogs. After 3 hours of dehydrating, Erik said he could not believe how much faster his product was drying. He figured it would be four times faster than his current system. He decided he had seen enough and moved forward with purchasing the next larger model, our Commercial Jerky Dehydrator AirFlow 260 dehydrator. Another happy satisfied customer! 2018

See YouTube video on how the AirFlow Dehydrator works – click picture above.

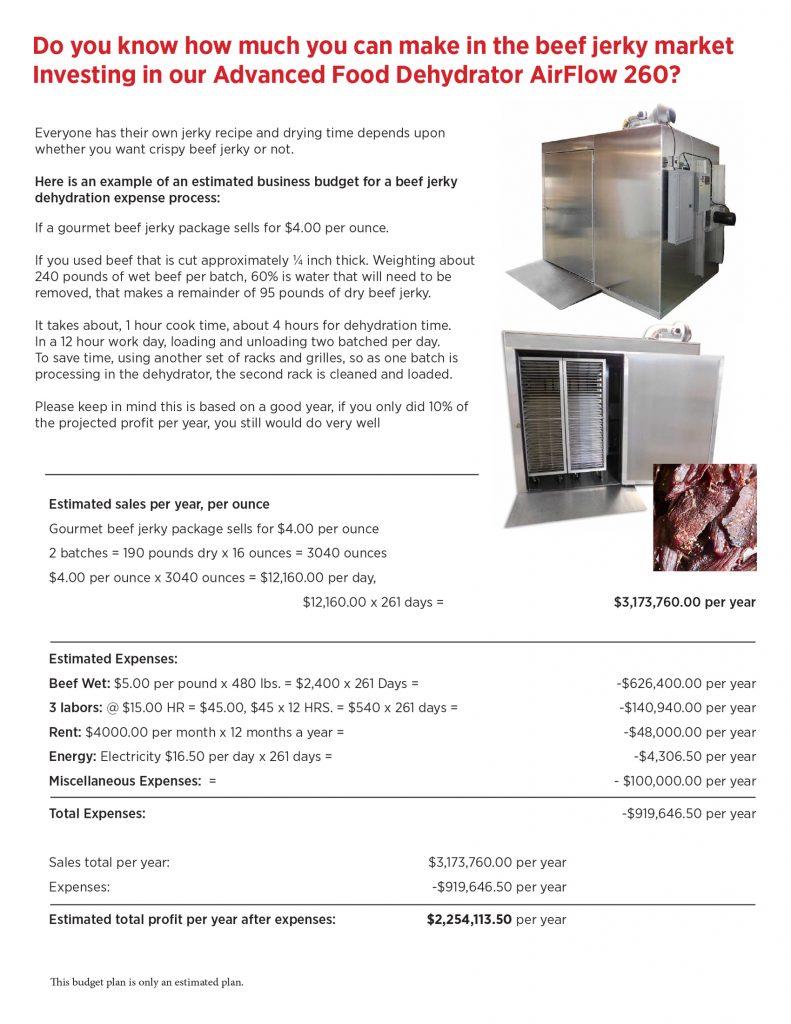

Commercial Jerky Dehydrator – Air Flow 260 square feet Dryer

The AirFlow 260 commercial jerky dehydrator, with 260 square foot of tray drying area that will hold approximately 480 pounds of 1/4 inch sliced meat to make beef, chicken jerky or pet jerky products. Our AirFlow 260 easily dehydrates fish, vegetables, fruit, pet food, beet powder and more.

How this dehydrator works

The AirFlow 260 food dehydrator includes one powerful heavy duty energy efficient fan, which circulates the air many times throughout all the trays to assure even air distribution. Our exhaust fan is a high quality Germany made with an EC motor that is 100% speed controllable. The exhaust fan controls how much fresh air enters the dehydrator as the humid air is vented out the exterior of the building. Whether you are dehydrating meats to make jerky, dehydrating fruit or vegetables, our AirFlow 260 powerful 19,600 watt heater will quickly get the job done, resulting in saving you time and money and the environment.

What is so special about this AirFlow 260 dehydrator?

The AirFlow 260 dehydrator uses an energy saving circulation fan motor that is 85.5% efficient. A commercial temperature controller will turn the heater off and on once your desired temperature has been reached. The walls, ceiling and floor come fully insulated which as a result faster drying time and saves energy and money due to low heat losses.

Why do we say this is a Commercial Jerky Dehydrator?

Most Importantly, this dehydrator and all our dehydrators make beef jerky to the USDA Standards. We offer a lethality cycle, this is a very important step when making beef jerky. The proper safe way to dehydrate beef is to raise the temperature of the beef in a closed chamber, like our AirFlow 260, set your temperature controller to 150 to 190 degrees depending on your process temperature, close the damper, go through your (lethality step or cook time) with full humidity. This step is done before any dehydration takes place. Once it reaches the set temperature and humidity for a period of time, you simply flip a switch. This will open the damper and turn the exhaust fan on so the wet humid air can be vented out of the building.

This is a link to the government USDA on how to make Jerky and food safety (fact sheet).

The AirFlow 260 can be easily expanded in the future: Commercial food dehydrator AirFlow 260 expands to our AirFlow 520 by adding more flat trays at 5/8″ spacing.

It has been said by some of our customers, that this dehydrator equipment is one of the best and is powerful enough to get the job done quickly. As a result, by saying this, they may process over one million dollars worth of beef jerky with the AirFlow 260 dehydrator. (see our estimated cost below)

Made in USA

To download a pdf of the above sample quote please download.

Features/Benefits

- 3 phase load center

- Commercial / Industrial temperature controller, turns heaters on and off once your set temperature has been reached

- Digital timer turns off the machine at your set time

- 1 – heavy duty electric 19,600 watt heater coil for a faster process (Lethality cycle), cook time and dehydration time

- Heavy duty solid state relays

- #1 – Heavy duty 1 HP premium 85.5% efficient electric motors, with extra-large ball bearings for long service life

- #1 Heavy duty exhaust fan with energy efficient EC motor is 100% speed controllable

- Potentiometer to control exhaust fan motor speed

- #1 Heavy duty electric damper closes during the lethality cycle and opens during the dehydration cycle

- Precision ground drive shaft

- Heavy duty stainless steel ball bearing with food grade grease

- All stainless steel bolts and screws

- Heavy duty stainless steel hinges

- Heavy duty stainless steel commercial latch

- 2 – Heavy Duty NSF racks

- 80 – Heavy Duty Stainless Steel grilles

- Frame: Heavy Duty 6061 T6 Aluminum with welded joints

- Floor Fabrication: Heavy Duty Aluminum 6061 ribs with welded joints welded to a heavy duty 3/16” thick Aluminum plate floor

- Floor Insulation: 2 inches of Class 1, Polyisocyanurate insulation

- Wall insulation: 2 inches of Class 1 Polyisocyanurate insulation

- Ceiling insulation: 2 inches of Class 1 Polyisocyanurate insulation

- HOBO USB Micro Station data logger, logs humidity data that can be downloaded to your computer

- Smart Sensor

- HOBO ware

- USB Cable

- Electric damper

MEASUREMENTS

- Approximate size: 96 inches long x 61 inches wide x 80 inches high

If you have any questions please email us at Envsolar@comcast.net. Click here to view AirFlow_Dehydrator 260-SpecSheet